Traditionally, manufacturing was completed in a single process. However, currently, users have become more demanding. The market is also packed with a wide range of options. This means that manufacturers cannot afford to release faulty products in the market. Doing this would ruin their reputation as clients may not purchase their products even after they have addressed the pointed out issues.

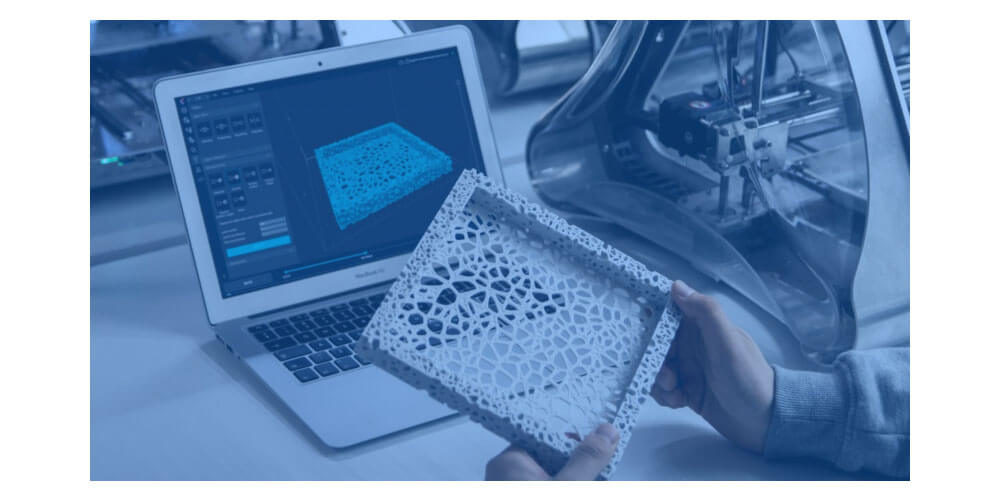

For such a reason, prototyping services were introduced. Rapid prototyping refers to a wide range of techniques to produce a product for testing or presentation before the actual product manufacturing is done in bulk. Rapid prototyping is used in a wide range of applications which we will be discussing below.

Applications of rapid prototyping services

The introduction of stereolithography has led to the development of new technologies used in rapid prototyping. These technologies have also resulted in increased applications of rapid prototyping services. Below are some of the primary applications of rapid prototyping services;

1. Concept modeling

The primary and most common application of rapid prototyping is in creating concept models or designs. This is where you bring designs or models into life using rapid prototyping technology or techniques. Developers or designers apply rapid prototyping to bring their designs into life to avoid any speculations in designing.

Such helps the designers point out and eliminate any potential design issues before the final model is sent to the manufacturing department. In simpler terms, prototyping services are applied in concept modeling to eliminate mistakes in the engineering process.

2. Visual presentation

Industries also use rapid prototyping services for the visual presentation of their industrial prototypes. Creating and presenting a visual prototype helps designers get a picture of their idea, product, or invention. Most of the time, the visual presentations are presented to an audience for feedback.

The audience may be stakeholders, investors, and in some cases, the potential users of the product. The feedback received is used to make changes to the product design and make it better. Therefore, applying rapid prototyping services in creating visual presentations aims at testing and trying out new ideas, which will eventually lead to a final product or invention.

3. Testing product functionality

Rapid prototyping is also used for testing the functionality of a product. Here, product samples, also known as prototypes, are built, then their functionality is tested. The aim is to ensure that a product performs the purpose for which it was created. In this case, the prototypes act as a prop to test where replication, advancing, and improvements are required. Functional prototypes are primarily used in product development.

4. Direct product fabrication

Currently, rapid prototyping is also used for the direct fabrication of products. In this case, the products are intended for consumer needs. For instance, the medical and dental fields use rapid prototyping to make implants used by patients. Here, the design is determined by the patient’s individual needs and data. For example, it is used to produce earpieces and dental prosthetics.

Conclusion

Rapid prototyping gives developers and designers the chance to explore and realize concepts faster. The technology also helps them save money and time. In short, prototyping services help you recognize and correct any mistakes possible on the final product.