Prototypes are now part and parcel of the manufacturing industry. While prototype manufacturing is important, it might be a bit hard to comprehend. Then, a little bit of insight should help bring your idea to fruition.

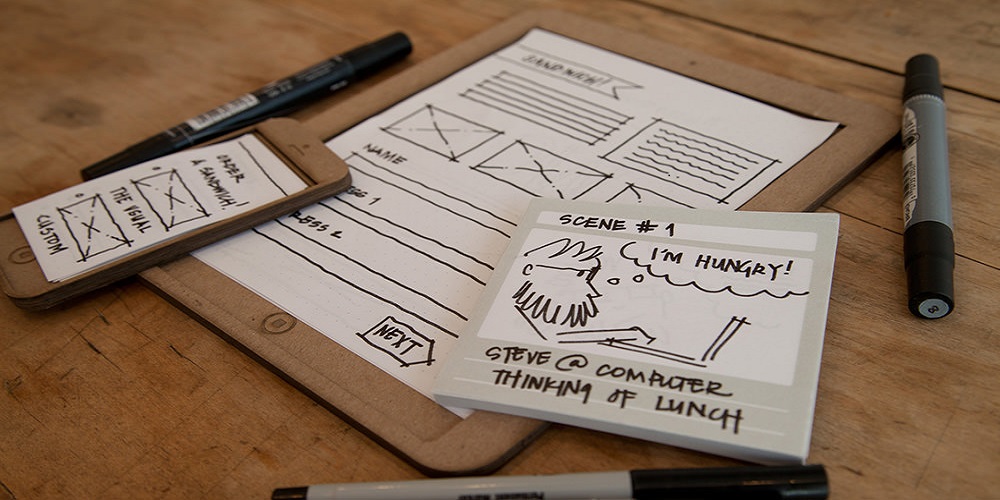

A prototype is usually created to set the standard for the final product itself. In other words, it is simply a design that depicts the attributes and functions of a product that is yet to be created.

They are generally made for the purpose of creating awareness for a product, showing the potential investors or target customers its functions and capabilities.

It is also an avenue to get useful feedback that can aid in further development of the actual product so as to ensure that it meets the requirements of its users.

Benefits of Making Prototypes

While a prototype may look like the actual item, it should only be considered as a visible and physical representation of what the final outcome should be.

This simply means that they are created for the purpose of giving potential investors a preview of what the actual item should look like and the functions it is to perform so as to enable them to determine how viable the investment is and whether or not to back the project financially.

Apart from being used in pitching investors, prototypes are also useful in the sense that they help facilitate the further development of a product.

Choosing a Prototype Manufacturing Company

Although there is no shortage of Prototype Manufacturing Companies, deciding on which one to work with can be somewhat challenging.

The following are some of the things to look out for when doing so.

1. Lead time

It is very important to know exactly how long the creation process should take. A good prototype-making company should be capable of stating how long it will take for your item to be created and fully functional.

Not only that, it should also be able to ensure that it follows through with the delivery date without any excuses.

2. Quality

While a design should be pleasing to look at, it also needs to be made as effective and durable as possible in order to meet with customer standards.

That said, the prototype manufacturer has to ensure that the prototype is made properly and from the right materials.

3. Customer service

This goes beyond performing regular customer service functions. A proper prototype manufacturing company should be able to work quickly and effectively especially when dealing with challenging aspects of the job and also adapt and respond to irregularities that might be encountered during production.

Dealing With Prototype Manufacturing Companies

Choosing a prototype manufacturing company is one thing. However, it doesn’t end there.

Although the agency might have been provided with detailed information regarding the item that is to be produced, crucial issues might arise later on, and for such issues to be addressed properly, the customer’s input might be required.

In some cases, the prototype manufacturing company offers suggestions to their customers that can help enhance their design.

However, such suggestions cannot be acted upon without the explicit permission of the customer.

Conclusion

At times, people tend to be worried about sharing information about their product ideas with the prototype manufacturer.

It should be noted that before disclosing any sensitive information about the product and before the creation process begins. The company is required to draw up a non-disclosure agreement to be signed by all concerned parties.

This prevents the company from disclosing any information concerning your product or re-creating a similar version for their own benefit.

Aside from this, providing conclusive information about what you require and collaborating with the prototype manufacturing company every step of the way should be more than enough to get the desired finished outcome.