Shot blasting and sandblasting are two distinctive processes that use different pieces of equipment. What’s common for both processes is that they heavily rely on their abrasive media. It is the one thing that makes those processes possible.

Here is an introduction to the world of abrasive materials.

Abrasive materials 101

Abrasive materials can be of metal, ceramic, organic, or mineral origin. Each abrasive material contains certain properties that make it suitable for certain types of sand or shot blasting.

Here are the top four properties of abrasive materials, regardless whether it is for a shot blasting or sandblasting operation:

- Size

All media particles are measured in “mesh”. Mesh is measured in holes per square inch.

- Density

The denser the particles are, the more mass per size they have, compared to lightweight media particles. The right media density is crucial to complete the process efficiently without damaging the treated surface.

- Shape

This is a critical feature for the surface finish. For example, angular shaped particles are more abrasive then round-shaped particles. The shape can determine if the surface will be extremely smooth, extremely rough, or anything in between.

- Hardness

Choosing the hardness of the particles can make the process go smoothly and efficiently, or can lead to irreversible damages. For example, hard steel particles can penetrate deep into some materials. If the treated surface is too soft it can even penetrate the surface and the damage can be substantial. That’s why it is essential to match the right media with the appropriate surface.

Shot Blasting & Sandblasting Abrasive Media Materials

Each abrasive material has its properties beyond the basic features such as density, hardness, size, and shape. Their selection primarily depends on the surface that is to be treated, not that much on the used methodology.

Here is a selection of some of the most common abrasive media materials used for both shot blasting and sandblasting operations.

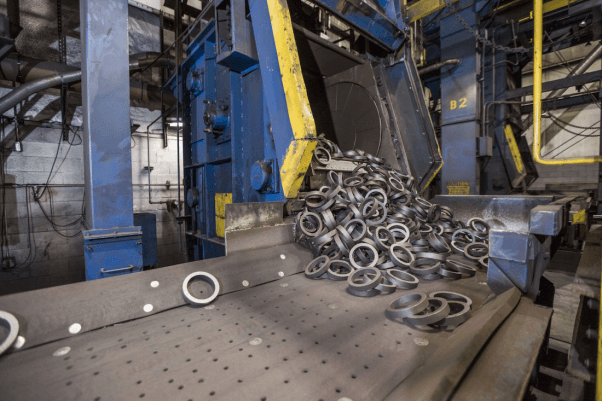

- Steel grit & steel shot

Steel abrasives are a top choice for heavy-duty operations. Steel grit is made in an angular shape, whereas steel shots are round.

- Aluminum Oxide

This is a low-cost, reusable abrasive that is perfectly suitable for hard surfaces that need fine polishing.

- Glass Beads

This is one of the softest media materials available on the market. They are made from soda-lime and are best suitable for soft surfaces.

- Plastics

These abrasives are made either from polycarbonate or polystyrene. They can vary in density, hardness, shape, and size. They are commonly used for the treatment of fiberglass.

- Silicon Carbide

This is by far the hardest abrasive media and it comes in all sizes, from the coarse grit to a fine powder.

- Walnut Shells

They are quite affordable and best suitable for plastic and soft metal surfaces.

- Sand

There aren’t many sandblasting operations that still use sand. That’s mainly because it is very hazardous and can lead to lung cancer. In the past, sand was the most common abrasive material for sandblasting.

Other abrasive materials widely used are staurolite, black beauty, and corn cobs.

In Conclusion

Now, when you know the types of abrasive materials, you need to start thinking about the next best thing – shot blasting machine manufacturers. Choose a reputable one and make your way into the surface preparation industry. Surface preparation and surface cleaning might not sound fancy, but it is a field of opportunities as the demand for the services it provides are ongoing, without any signs of stopping.