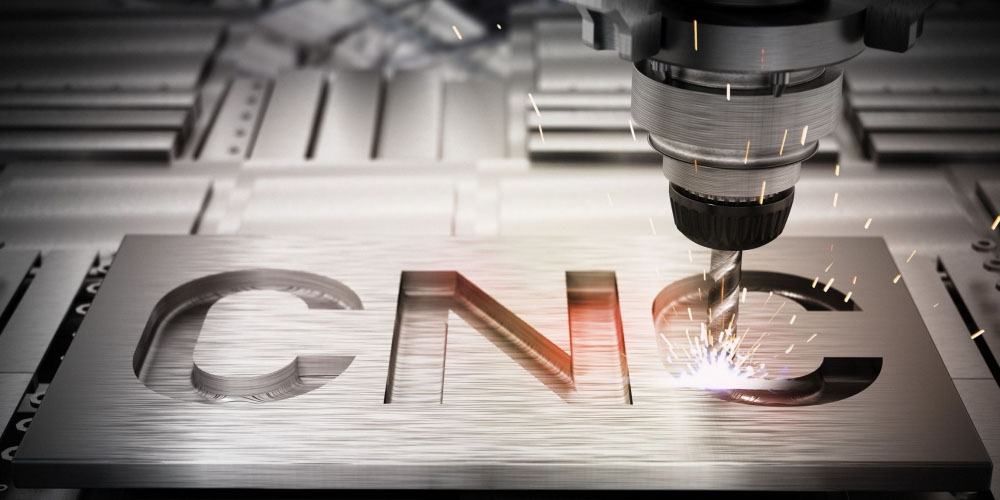

CNC machining companies use computer numerically controlled machines to produce various parts. These companies use a wide range of materials like metal, plastic, foam, and wood, to name a few. Compared to standard machining tools, CNC machining tools are faster; they produce smoother results, allowing for multi-tasking. The market features a wide range of CNC machining tools, which this post will cover.

Types of CNC machining tools

Below are some of the most popular CNC machining tools or operations

1. CNC machining drills

These tools are used explicitly for drilling purposes. CNC drilling is the process of developing cylindrical holes inside objects by using drill bits. In CNC drilling, an operator creates a computer-aided model using CAD computer software. The model is then fed into the drilling tools.

Before this happens, the model is translated into a language that the machines can understand. From there, the drilling machines are 100% operated by the computer. These machines feature various types and sizes of spindles. The role of the spindle is to develop holes featuring different lengths and diameters.

The holes are typically aimed for fitting machines, screws, and bolts. Radial, upright, and bench machines are examples of the most popular CNC drilling machines. Here, the drill bits are typically fed angularly or perpendicularly to the workpiece.

2. CNC milling machines

These machines handle milling processes. Milling can be referred to as removing materials from a large workpiece until a desired shape and design are achieved. CNC milling tools usually have multi-point cutting tools that are used for producing custom parts.

The CNC milling machines typically have a moveable top where the workpiece is placed as it is worked on. The cutting tools move in different directions following the rotation of the workpiece on the moveable top.

CNC milling machines can apply various types of materials, like glass, metal, and plastic, to name a few. Here, the objects are fed in a similar direction to help produce custom designs. The main benefit of these tools is that they can make products of different shapes and sizes.

3. CNC turning machines

These machines use single-point cutting tools for removing materials from a workpiece until the desired shape is achieved. They are also known as CNC lathe machines, and their working process is known as lathing. The materials are typically fed to the device while in a parallel position.

The machine’s cutting tools move at different speeds and directions. As this happens, the materials around the workpiece are removed. Most of the time, parts produced by CNC turning machines are usually cylindrical or round. They may also feature internal and external elements like threads and tapers.

Conclusion

Each of the machines or tools listed above is computer numerically controlled. This means that a computer explicitly controls its processes. This makes them more convenient, faster, easier to apply, and they produce better quality parts or products. It is also worth noting that the form of CNC machining applied depends on the design, made in the form of a CAD model.