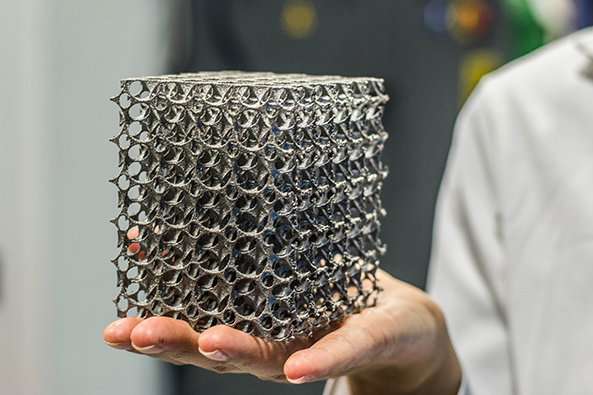

Initially glance it resembles a typical mirror, but it isn’t. It is a 3D-printed component, an innovation that Cupra, the efficiency spin-off brand of Spain’s SEAT, has actually started to implement in the growth of the new Leon Competición in partnership with HP. Greater effectiveness, dexterity as well as adaptability are the benefits of a system that is readied to revolutionize auto-growth according to Cupra.

” For the new Cupra Leon Competición we modeled the guiding wheel facility control component, hood air vents, door mirrors and also brake as well as water cooling inlets,” states Xavi Serra, the Head of technical development at Cupra Racing. These components were created using HP’s commercial-grade Jet Fusion 5200 3D printing remedy and included in the requiring development tests propounded the brand-new racing design.

This 3D printing innovation features multiple advantages. “The main objective is to have plenty of parts quickly. We can rapidly check a wide variety of designs as well as moreover because car advancement is now done in parallel, this innovation enables us to react swiftly to any changes in the design procedure”, Xavi mentions.

” The deal with Cupra demonstrates the power of 3D printing as well as electronic production– transforming the method the world layouts as well as manufactures”, explains Virginia Palacios, head of Systems Product Management, 3D Printing & Digital Manufacturing, HP Inc

. In touring automobile racing, the door mirror is a part which, according to the policies, must have the exact same form as the production car. The Cupra engineers went one action additionally. “We wished to add an additional function, which is to cool the motorist. We for that reason needed to develop an air intake in the optimal pressure area to attain this result”, Xavi shows. The area where these products are tested is the wind tunnel, where the 3D printed components are verified in specifically similarly as the remainder. “The bigger the range of parts we can evaluate in this center, the better. It allows us to make much faster progression”, claims Xavi.

As it is a racing auto, the final phase of advancement can just be accomplished in one place: the motor racing circuit. Much more especially, the Leon Competición with its 3D printed components was propounded the limit on the Portimao track in Portugal. “The outcomes were exceptional, as well as some were even shocking, due to the fact that we were seeking to push the material to its limits”, claims the Cupra designer.

” 3D printing is mosting likely to indicate a transforming point in the automotive sector by increasing lead times and HP 3D technology is aiding designers develop components that could not be produced with other modern technologies”, says Palacios. “This technology is as well as will continue to be type in many fields to make one of the most complicated suggestions a truth”, concludes Xavi.

Paul Benning, Chief Technologist for HP 3D Printing & Digital Manufacturing concurs regarding the future capacity of additive production in the vehicle field. Talking with PlasticsToday, he commented: “Historically, the automotive sector has actually depended on 3D printing technologies for prototyping. As metal as well as plastic 3D printing systems that assist in mass production are incorporated into the automobile setting, there has actually been a move toward the use of 3D printing for major last part manufacturing– as seen with Volkswagen’s news to include HP’s Metal Jet technology right into its item roadmap for the manufacturing of new electric automobiles.”

Includes Benning: “One chance related to automated setting up is the creation of new approaches and development of materials science, including the ultimate capability to integrate steels and also plastics together right into the exact same production cycle. While there’s presently not a printer that can incorporate both materials because of aspects such as processing temperature level, it will certainly be a game changer for the vehicle market when this capacity gets here– especially as a cost and time saver.”

This is part of HP’s larger vision for not simply automotive applications, but for all sectors leveraging 3D printing modern technologies. “We have a lot more progression to make in the improvement of automated setting up, however we imagine a future where it will certainly involve fruition on the factory floor within the following 5 years,” wraps up Benning.