When most people think about laser marking machines, the first thing that comes to mind is the ability to permanently mark a product with a serial number or other identifying information.

While this is undoubtedly one of the key benefits of using a laser marking machine, businesses enjoy many other advantages. In this blog post, we’ll discuss some of the top advantages of using a laser marking machine in your business. Stay tuned!

What is a Laser Marking Machine

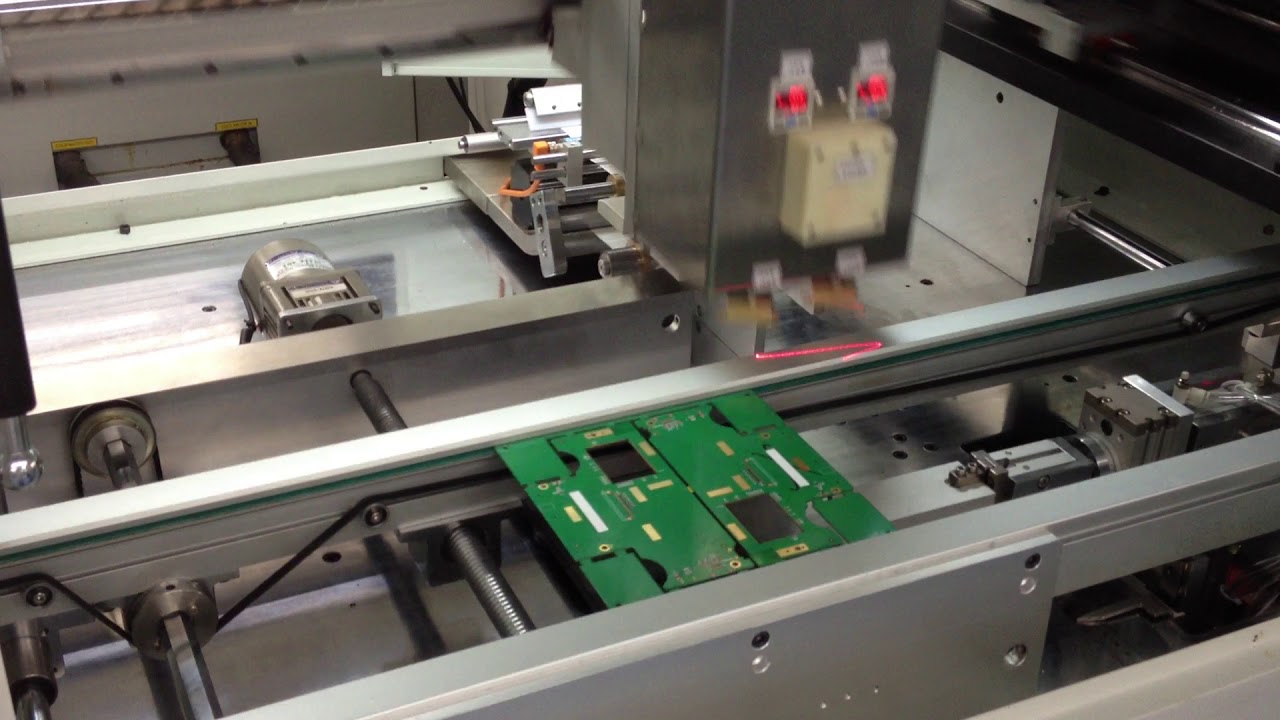

A laser marking machine is a device that uses a laser beam to mark an object. The machine can be used on various materials, including metal, plastic, glass, and wood.

Laser marking is a permanent form used to create text, logos, and other designs. The laser beam vaporizes the top layer of the material, revealing the darker layer beneath.

This process is repeatable and produces consistent results. Laser marking machines are exact and can produce markings with speeds of up to 5000 characters per second.

Advantages of Laser Marking Machines

Laser Marking brings so many benefits to the table, that it’s hard not to be dazzled. Let’s explore a few advantages.

Increased Productivity

In any factory or workshop, productivity is key. That’s why more and more businesses are investing in laser marking machines. In addition, laser marking systems are much faster than traditional methods such as printing or engraving, making them well-suited for high-volume production environments.

As a result, industrial laser marking machines are an increasingly popular choice for product identification and traceability in various manufacturing settings – without the need for costly retooling or manual labor.

Enhanced Quality

Another great advantage of using a laser marking machine is that it can help you enhance the quality of your products. When you use traditional marking methods, such as stamps or labels, there is always the potential for error.

These machines offer several advantages over traditional marking methods, such as dot-matrix printing or Inkjet printing. It is a non-contact process, meaning there is no risk of damaging the product surface. The laser beam can also be precisely controlled, making highly accurate and consistent marks.

Cost Savings

Cost savings are one of the main reasons factories switch to laser marking machines. When you use traditional marking methods, such as stamps or labels, you often have to replace them frequently. This can end up costing you a lot of money over time.

However, with a laser marking machine, you’ll only need to replace the consumables (laser beam, focus lens, etc.) when they run out. This can help you save a significant amount of money over the life of your machine.

Increased Flexibility

Laser marking machines offer a high degree of flexibility when it comes to the marking of industrial components. These devices can be used to create various markings, such as logos, barcodes, and serial numbers. Whether you need to mark small or large objects, you’ll be able to do so with a laser marking machine. This can help you save time and increase your productivity.

Environment-Friendly

Unlike other methods of marking, such as chemical etching, laser marking does not require using any hazardous chemicals. In addition, laser marking produces very little waste material, as the energy from the laser vaporizes the surface of the material being marked. As a result, laser marking is a highly efficient and eco-friendly way to create markings on various materials.

Conclusion

Laser marking machines are becoming increasingly popular for a wide range of applications, such as product identification, serialization, and anti-counterfeiting. A laser marker is a perfect option if you’re looking for a reliable machine that can produce high-quality markings quickly and easily.