In almost any industry you find yourself today, the importance of a 3D printer cannot be overlooked. It seems to have changed the way the engineering and manufacturing industry operates. The world is abuzz about the impact that 3D printers have made.

While almost everyone has certainly heard about 3D printers, not everyone really knows how it works. If you are in this situation, then we might be able to help.

What are 3D printers?

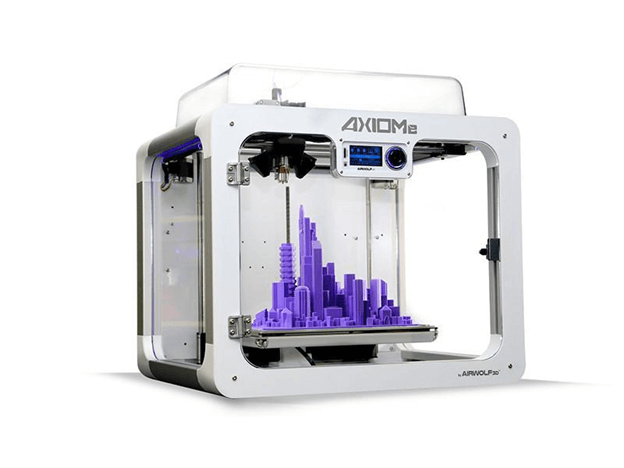

3D printers are the latest technology in the additive manufacturing line. Additive manufacturing is all about creating an item or objects through the addition of layers one step at a time.

Other types of technology which also belongs to the additive manufacturing line include 3D Layering as well as the popular stereolithography. However, the impact of 3D printing has surpassed them all.

How do 3D printers work?

Well, how do they work? The first thing it does is creating a graphic model of the object it intends to create. Graphic models can be created through various means such as software applications. This aspect of 3D printing is the part where most human efforts are needed.

Once the graphic model and design are completed, the next thing is to slice the model. Not literally slicing but digitally. This is another important step. While humans are able to take in the digital model and understand its concept in its raw form, 3D printers do not possess this ability.

What the slicing process achieves is that it takes the graphic model and divides this model into various parts. These parts are often called layers.

Once the layers are all separated, they are then taken to the 3D printers one at a time to get the printing done. Most people will use Astroprint for this procedure. However, they are a number of options that are open to you.

Another thing which this process will achieve is the creation of support columns. After this stage, the 3D printer then takes over the entire process. Several layers will be printed using the instructions which have been provided.

The particular methods it will use depends on the factors involved. It will also depend on the type of 3D printer that is being used. One of the best 3D printers will be the Ender 5 3D printer. The 3D printer will then use tools such as the inkjet to add other things to your object. This includes waxes and polymers.

When using a 3D printer, it is important to remember that 3D printing can take hours to complete. Sometimes, it can even take days. The determining factor behind the length of time is the size of the object and how complex its design is.

Getting a 3D printer

If you are in the manufacturing industry, then your business truly needs a 3D printer. Without it, you probably will be facing more costs as well as a struggle to keep up with your rivals.

With so many good 3D printers around, it is the best decision you can make.